Food Case Study - Jam Line Relocation

Novatec recently relocated a jam manufacturing line from Worcestershire to Wigan

Background

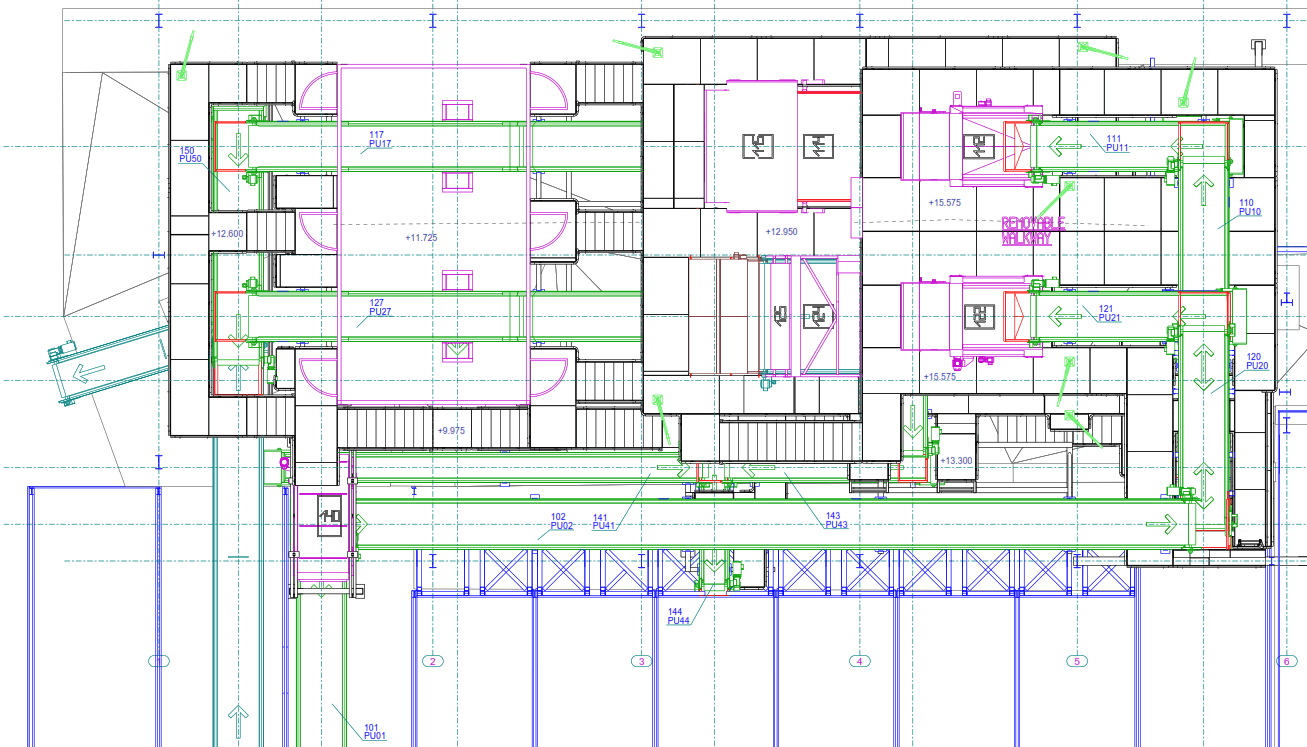

Following the sale of the equipment, Novatec was appointed to undertake the relocation of an operational jam manufacturing line from a factory in Worcestershire, to it's new home in Wigan.

The project required a quick turnaround, from quote to completion, to ensure product could be manufactured in the new facility prior to stock depletion.

Using our documented systems for the preparation and execution of this type of project, Novatec were able to successfully complete our scope of work ahead of the customer's schedule, leading to another five star review on completion:

"Premium quality work by a premium quality team...very health & safety conscious

...Appreciate all your hard work"

Novatec Scope

Novatec had responsibility for the full mechanical dismantling, removal, relocation and reassembly, working alongside the customer's appointed electrical contractor.

Following cessation of production in Worcestershire and preparation of the necessary pre-start documentation, the team set to work on:

- Safe isolation and lock-off of the necessary services

- Full match-marking, photographing, bagging and tagging

- Mechanical disassembly of the equipment and interconnecting pipework

- Lifting, handling and removal of the equipment to the site laydown area

- Sheeting of the equipment in the laydown to protect from the weather

The equipment was located over three levels at Worcestershire, therefore much of the higher level machinery had to be carefully lowered through the upper floor level, prior to being removed from the building.

All lifting and handling operations, as always, were fully planned and managed by our in-house CPCS Appointed Person and safely executed under the control of our CPCS Lift Supervisors, who ensured all practical aspects of the lifts were completed safely and in accordance with approved standards.

Following dismantling and removal to laydown, all machinery then had to be loaded to transport out of normal hours to prevent interference with the site's usual operations.

On arrival at Wigan, the machinery, platforms and interconnecting pipework was all offloaded, moved to position and reassembled in record time - ready to make jam!

If you'd like further information on this project, similar work we've completed over the years, or If you have a similar requirement coming up and you need some advice or assistance, please feel free to get in touch to discuss how we can help.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factory relocations for blue chip clients and in all industries from food production to waste recycling (and everything in between). Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

If you need someone you can trust to look after your machinery needs - in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning - get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.