Why Move Your Machinery

In this article we look at some of the reasons you may want to move your machinery...

The reliable operation of your production or process plant & machinery is obviously a major priority in the success of your business. As each new machine or line was integrated into your facility, there were no doubt many planning meetings and considerations made to arrive at the correct position of the equipment.

There are, however, situations where it may make sense to move your machinery and this article takes a look at a number of these, along with how the team at Novatec may be able to help you.

(1) Replacement of old machinery

Changing an old machine just because of its age is just plain rude!

However, more often than not as a machine ages, it may tend to break down more frequently, reducing production efficiencies and creating bottle necks. Replacement parts may become obsolete.

The machine’s safety systems may no longer comply with current legislation, perhaps making them unsafe for your operators and maintenance personnel.

When the time has come, you’ll want to remove the old machine and replace with a more up-to-date model as quickly, safely and efficiently as possible.

(2) Reorganising floor space

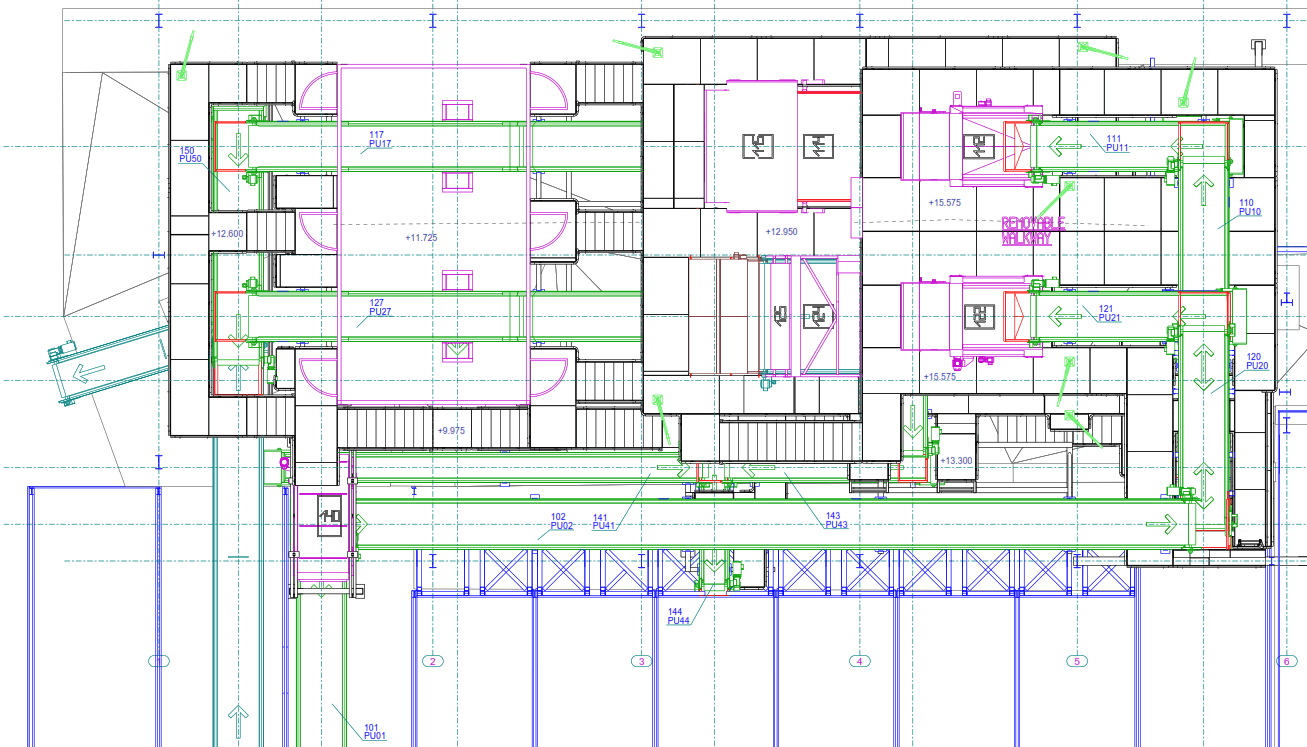

While we’d all like to think due time and consideration was given to planning the integration of machinery and equipment into your facility, prior to installation. In reality, the new machinery was possibly forced into the space available at the time.

This approach can certainly help to get your new machinery running and contributing to production output as quickly as possible, however, it inevitably leads to poor production flow, inefficiencies and bottlenecks.

Regular time and motion studies can help to highlight areas of concern and may show the need to shuffle around plant and machinery to improve workflow. Carrying out a simple cost and feasibility study may show an obvious pay-back in the short-term upheaval.

If the need to reorganise does become apparent, you’ll want to talk to an experienced professional machinery movement specialist, ideally one understands the priorities of a manufacturing environment and can manage the entire project, like Novatec Engineering.

(3) Premises relocation

With the growth and success of your operation, you may end up at a point where a re-shuffle of equipment isn’t enough, and you need to move to an alternative premises.

This is quite an undertaking without the right relocation partner on board and will require a great many additional considerations to ensure you’re not jumping from the frying pan into the fire.

You’ll need to consider things such as additional buffer stock, or outsourcing parts of the production process to see you through the extended downtime, transport links for goods in and out, workforce locality (if moving a significant distance), site services requirements (power, air, water, effluent discharge, etc.) and availability, floor condition and suitability, etc., etc.

This could be a significant project and one that Novatec is very experienced with. If a premises relocation is something you are seriously considering, give the team a call to discuss and we’ll do all we can to help.

(4) New product lines

Quite often, a forward-thinking manufacturing operation will develop new products that require the introduction of a completely new line into their existing facility (or even a new facility of its own).

The machinery manufacturer will typically be involved from an early stage to help with the design and layout process, however, the early assistance from an experienced machinery movement & installation company would pay dividends, to ensure the work done on paper can be physically achieved in reality.

(5) Selling redundant machinery

At the natural end of a particular product, machinery that is no longer useful to you may still have value to someone else. Rather than just scrapping this equipment, it may make sense to sell.

Novatec works with a number of the larger industrial auctioneers and can make an introduction, if required.

If going down this route, the auctioneer would typically survey the equipment and advise the likely sale value, then arrange pictures, listings and viewings before the final sale and handing over of proceeds (less their fees).

The purchaser would normally be responsible for arranging for removal of the equipment, but you’ll want to ensure the machinery movement contractor involved can work safely and with minimal disruption to your operation as possible.

(6) Machinery maintenance and upgrades

As a final area for consideration, you may simply need the assistance of a heavy handling specialist to get involved with certain aspects of maintenance or machinery upgrades – particularly where heavy components, such as large motors & gearboxes need replacement.

Again, working with a company that understand production requirements and can integrate with your existing maintenance team, is essential in carrying out the replacements quickly, safely and efficiently.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factories for a variety of different clients and in all industries from food production to waste recycling (and everything in between). Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

Trust us to look after your machinery needs in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning.

Get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call 01634 757455 or email the team at office@novatec-engineering.co.uk