Case Study - Shredder Replacement

Novatec remove a 27-tonne shredder and install a new Untha ZR2400 in its place

Background

Novatec was recently contracted by Untha UK Ltd. to carry out the removal of a waste shredder, weighing in at 27-tonnes, and replacement with a new Untha ZR2400 machine (shown above) at H Brown & Sons.

The Stoke-on-Trent based waste management company has used UNTHA shredding technology within its alternative fuel production plant for over a decade, but following 11 years of operational service, they have made the decision to upgrade to the newly launched ZR machine.

The new machine will process the same variety of input materials – a multifaceted mix of commercial, industrial and other bulky wastes – transforming them into a 200mm fuel for UK Waste to Energy conversion.

However, following extensive on-site trials, the new machine has been shown to increase its throughputs by up to 30%, thanks to UNTHA’s ongoing innovation.

Novatec Scope

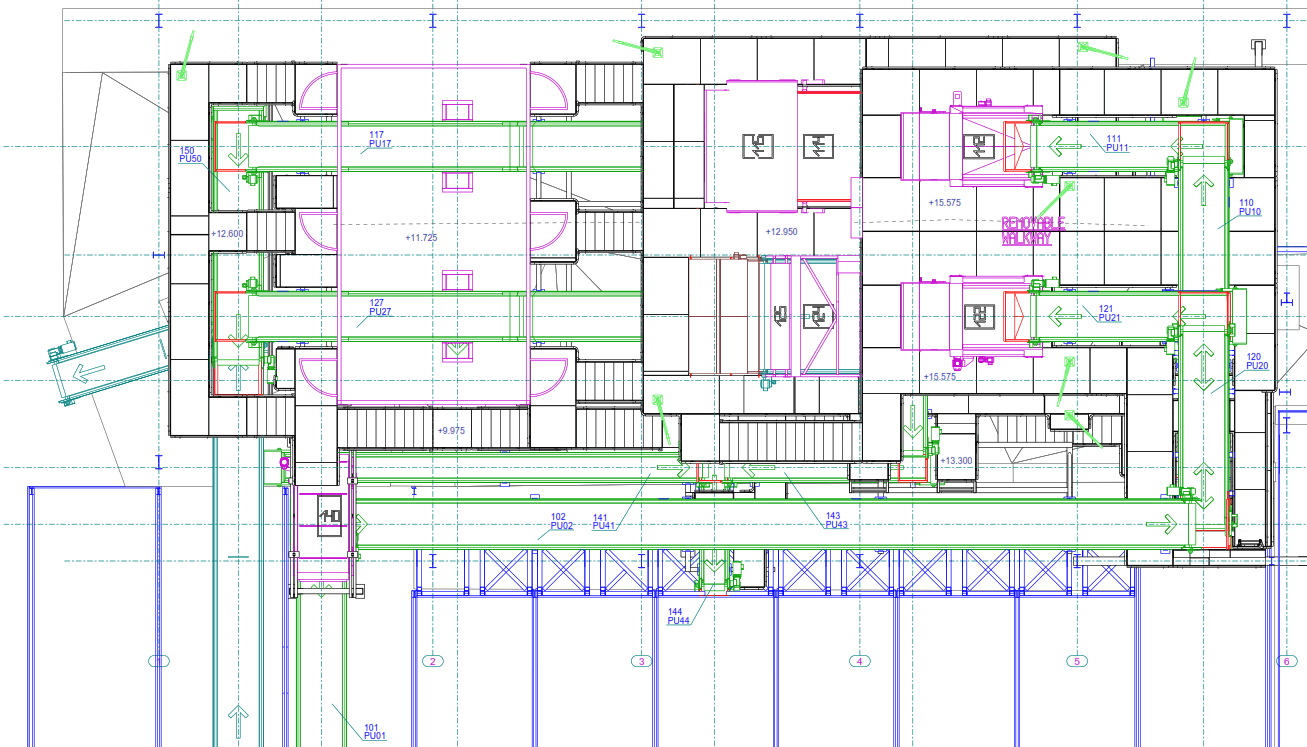

As well as the careful removal of the redundant XR shredder and stand - which had been sold on to another site for continued use - Novatec also had to remove the control panel, hydraulic pack and chiller from within an adjacent control room.

Following the removal, the delivery of new equipment was received and offloaded, prior to installing into position, with new legs, chute and loading hopper, as well as the new control panel, which was skated into the position vacated by the original panel.

All lifting and handling operations, as always, were fully planned and managed by our in-house CPCS Appointed Person and safely executed under the control of our CPCS Lift Supervisors, who ensured all practical aspects of the lifts were completed safely and in accordance with approved standards.

The mechanical works undertaken by Novatec, were completed successfully to schedule, over a two-week period.

If you're looking for a safe, reliable and professional machinery contractor to work with your chosen OEM for the installation of new machinery at your premises, feel free to get in touch with the team using the links below.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factory relocations for blue chip clients and in all industries from food production to waste recycling (and everything in between). Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

If you need someone you can trust to look after your machinery needs - in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning - get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.