What is a Rigger & why do you need one?

Would you let your window cleaner service your boiler?

If you’re like most sensible people, the answer’s probably ‘no’! Nothing against your window cleaner, but you obviously want a suitably skilled and experienced person to fit the role.

Believe it or not, we still get calls from new customers to rescue them from a machinery movement mishap, as a result of engaging an inexperienced (no doubt cheaper – but then you get what you pay for!) contractor to handle their valuable equipment.

As we’ve already established, you understand the importance of having the right person for the task, but it got me thinking about how many people, with machinery handling requirements, may not know what a Rigger is and the important process we go through to ensure your equipment is safely positioned and put into service with minimal disruption.

With that in mind, this week’s post goes into just that...

What is a Rigger?

In our case the term Rigger (and Rigging), relates to machinery handling and refers to both the equipment used to move / handle a machine (or its component parts) and the action of designing & installing the equipment in preparation for the actual machine movement.

Riggers typically design and install the lifting or movement equipment needed to raise, roll, slide or lift heavy objects, using appropriate tools, such as cranes, skates, chain blocks, jacks, wire rope, turnbuckles, slings, shackles, master links, lift trucks, hydraulic gantries, etc.

This may be for a single machine movement, the replacement of a heavy or awkwardly positioned component during a maintenance operation, or the assembly of multiple parts during a system installation.

In all cases, the involvement of a suitably qualified and experienced Rigger from the start, is essential to ensure a safely executed operation.

At Novatec Engineering, our extensive Rigging experience in a vast variety of industries, coupled with our detailed planning, effective management and world class execution, means we are routinely trusted by many industrial and manufacturing professionals to handle their high value plant & equipment, often negotiating seemingly impossible to access spaces.

What does the Rigger look for before preparing the movement plan?

In order to achieve a successful Rigging operation, there are a number of areas that need our attention:

(1) The load itself

Before a suitable movement plan and the most appropriate rigging can be determined, an assessment of the load must be made. This will include determining the item’s weight, overall size, centre of gravity, existing load handling points, any free moving elements that will need restraining, delicate areas that will need additional protection, etc.

(2) The movement route

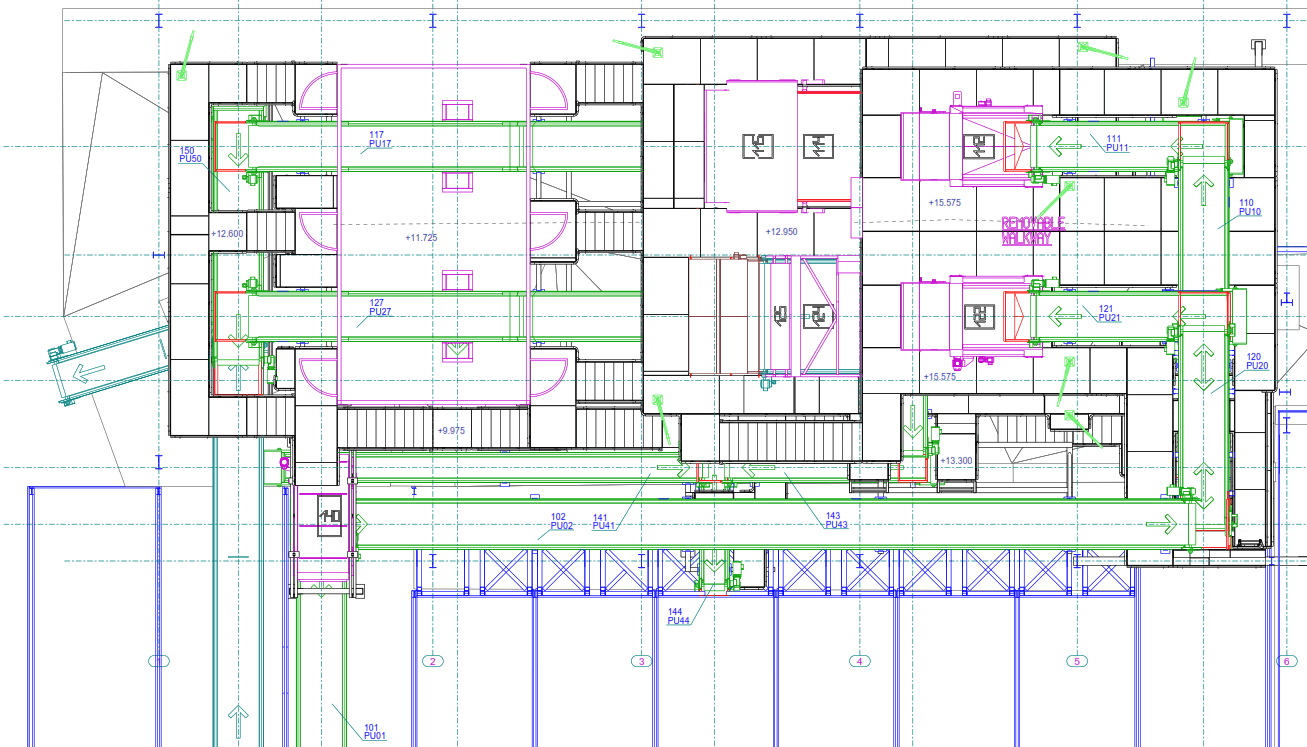

Once the load details have been recorded, the Rigger must assess all areas of the movement route, from start to finish, to identify any potential hazards to the operation.

This will include everything from the obvious (is there sufficient width, headroom, etc. along the movement route), to the less obvious, such as ground camber or gradient, step changes in level, weak spots in the floor (which you can almost guarantee will be found by a jack or skate if ignored!).

At this stage, the Rigger will also assess the existing use of all areas, in order to determine any risks associated with third parties (the client’s personnel, visitors or the public) or surrounding property and to determine the appropriate control measures to mitigate those risks.

The details from (1) & (2) above, will be collated into the Rigger’s survey report and used to prepare the final movement plan and details of the appropriate resources to be used.

What does the Rigger do during the operation?

(1) Communicate effectively

The Rigging Foreman (Lift Supervisor) will firstly ensure the documented movement plan and methodology are clearly communicated to the Rigging team and anyone else likely to be affected by the operation (client personnel, other contractors on site, etc.). This will include ensuring access routes normally used by third party personnel or the general pubic have been correctly closed to prevent unsafe entry into the movement area.

During the operation, the Rigging team will keep communicating with each other, either verbally or with the use of industry recognised hand signals, to ensure all elements of the movement are controlled and carried out safely.

(2) Make proper use of the tools and equipment provided for the task

The Rigger will ensure each item of equipment and their associated accessories, are personally inspected prior to use to ensure they are fit for service and appropriate for the task.

Being trained and experienced in the use of all manner of Rigging equipment will ensure the tools provided for the task will be correctly used within their design capabilities at all times.

If there is any doubt about the safe use of an individual item of equipment, or the Rigging arrangement in general, the Rigger will call a halt to operations for further review.

An experienced Rigger knows too well what the consequences of an unsafe lift could be and will never take the risk with his team or your people, plant and property.

(3) Ensure the means to correctly control the load are in place

The Rigger will ensure the appropriate controls are in place to prevent the unintentional movement of the load. Typically, this would include the use of tag lines, restraints, steel rope, slings, chocks, wedges, packing, etc.

(4) Be mindful of the centre of gravity and weight distribution

Following from the information gathered during the planning phase, the Rigger will continuously consider the machine’s centre of gravity and weight distribution, during all aspects of the move. This is particularly important during jacking and skating operations to ensure the load is not toppled..

Why take the risk?

Don’t risk your machinery or the safety of your personnel - Trust in the experience and expertise of Novatec Engineering to get the job done properly.

Over the years, our team has handled everything from a single machine movement to complete factories for a variety of customers and in all industries from food production to waste recycling (and everything in between).

Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

Trust us to look after your machinery needs in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning. Get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call

01634 757455 or email the team at

office@novatec-engineering.co.uk