Don’t let the ground swallow your valuable machine!

The Importance of Understanding Ground Conditions During Plant & Machinery Movements

When planning and undertaking a machinery movement project at your site, whether it’s to move existing machines to create an improved workflow or bringing in new machinery to increase production, it’s important to consider all aspects to ensure the task can be completed safely and without undue cost or downtime.

An often-overlooked area can be found directly below your feet. Ground conditions can provide many opportunities to topple a machine during relocation, with the obvious potential damage to personnel and property.

It is important a competent person surveys all areas where the machine will travel, including loading and unloading positions, as well as the full movement route. The following items should give you enough information to be able to carry out a decent assessment yourself. However, if you are in any doubt, it’s always worth bringing in someone, like Novatec Engineering, with the necessary experience.

Floor / Yard Construction

The internal floor and external yard / roadways will have been designed to suit the use of the building at the time of construction. If the building was constructed specifically for your company’s activities this should have taken account of vehicular access (HGVs) and any mobile plant usage (warehouse forklifts, etc.).

Whilst the construction design may have considered the size and types of machine to be used within the building, it is very unlikely that the movement of those machines into position and the types of plant and equipment required for the movement would have been considered.

Quite often, the building use has changed over the years, so none of these considerations will have been made.

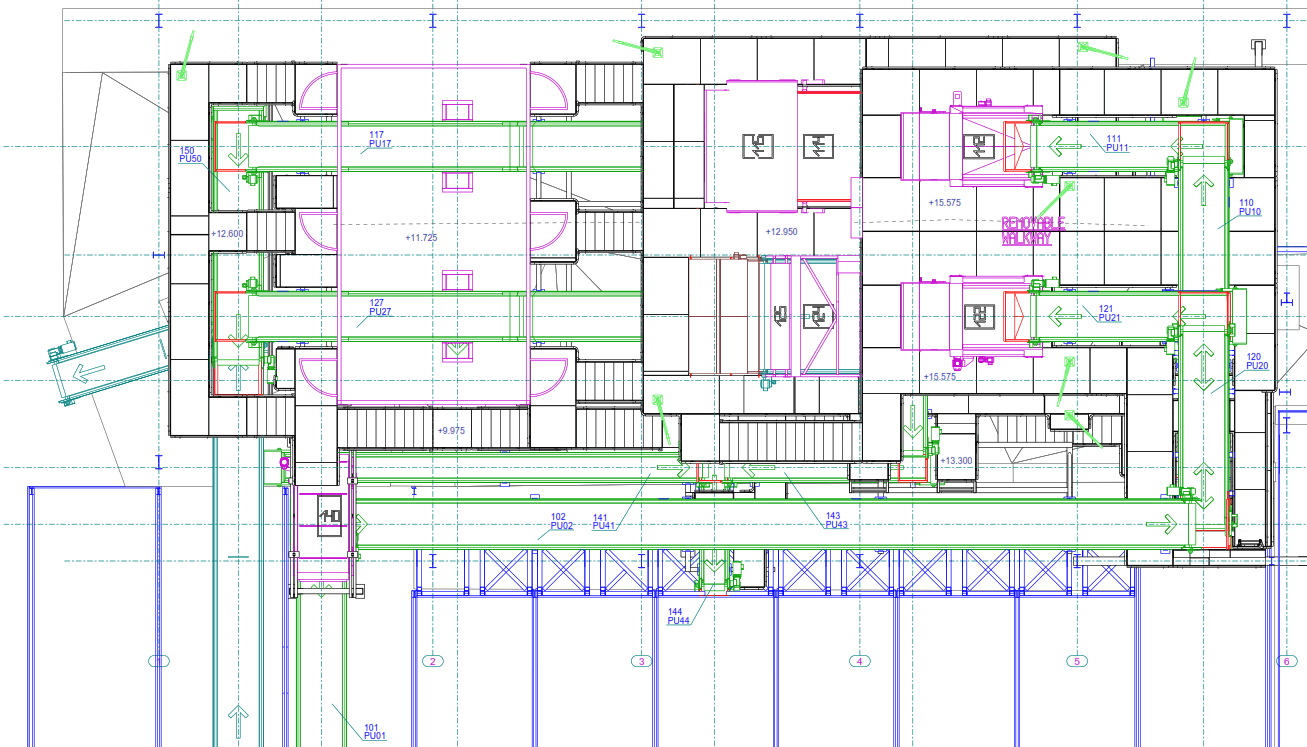

Where possible, original construction drawings should be consulted to ascertain the ground construction. These would normally be available as part of the Health & Safety File handed over when the building was constructed (depending on its age) and hopefully, updated as future projects have been undertaken. If these drawings are available, they can also be used to ascertain the position of drain runs and other underground services.

In our experience, these drawings are usually not readily available (for a variety of reasons), so you would need consider how the ground is currently used. In other words, do you have regular HGV deliveries, have these caused any damage to areas of the yard, have previous heavy machines been moved along the same route, if so, were any special precautions taken or subsequent damage witnessed, etc. Any areas of previous damage would need to be investigated further.

If there is particular cause for concern as a result of the visual inspection, it may be necessary to take a core sample from specific positions or carry out a ground-penetrating-radar (GPR) survey. Core drilling is a relatively straightforward process and one that Novatec Engineering can help you with, if required, however, it obviously leaves holes that need to be repaired (from the core itself and the fixings for the drilling rig). GPR avoids the mess but uses specialist and expensive equipment to carry out the survey.

Load Bearing Capacity

The primary reason for understanding any floor construction is to determine the maximum load bearing capacity and any weaknesses (from drain runs, etc., as above).

It is rare to receive specific maximum ground bearing capacity information, generally because the information just isn’t available. This is why it’s important to involve a specialist in any investigations and an experienced professional machinery movement contractor will be able to make the necessary assessment and know where to get additional advice, should this be necessary.

Again, core samples could be utilised, and these can be analysed by specialist laboratories for further information in critical applications.

Your machinery movement contractor will need to calculate the loads to be imposed on the ground during the movement operation and these imposed loads will be dependent on the different items of plant and equipment specified for the movement, i.e., plant outrigger loads, machine skate or jack surface area, etc. These will most definitely be much higher than the loads imposed by the machine itself.

Where surface water drain runs, etc. cannot be avoided, it will be necessary to utilise suitable protection measures to allow the imposed loads to be safely transferred to the surrounding ground.

In addition to the movement route, an assessment of the floor at the final installation position will need to be made. The floor will need to be suitable to receive any fixing bolts and to ensure they remain securely in position during normal operation.

Typically, with heavy machinery, there will be vibrational and shock loads imposed on the floor during normal operation of the machine (although, the machine manufacturer should have considered this in the design of the floor mounts). So, in addition to ensuring the floor is suitable for the dead weight of the machine, these must also be considered.

Machine Pits

Where the machine is to be lowered into a pit within an existing floor, the consideration of imposed loads must be extended to the design of the sidewalls of the pit.

Any loads imposed by machine skates, etc. will be applied to the pit walls as the machine approaches the opening.

You (or more appropriately, your machinery movement contractor) will need to consider carefully the equipment used to transfer the machine up to (as well as in to) the pit to avoid failure of the pit wall and surrounding floor level.

Other Considerations

During an assessment of the ground conditions, it would be wise to check for excessive slopes, cambers or changes in level along the route. These conditions may affect the weight distribution of the machine during movement, causing a temporary increase in ground loadings to one side or corner of the machine, which in turn could lead to ground failure.

Any areas of floor with specialist coatings should also be identified to allow the necessary protection measures to be identified. Whilst damage to these areas may not lead to ground failure, it may involve costly repairs (depending on the coating) and potential pedestrian trip hazards.

Final thoughts

Ground conditions throughout the movement route should be carefully considered to ensure your heavy machinery can be safely transferred to position. It is always advisable to involve your chosen machinery movement contractor early on to ensure the appropriate control measures are identified and correctly implemented.

The team at Novatec Engineering have many years of experience with every type of machinery movement and installation imaginable. If you would like help with any of the above for your next machinery movement challenge, please don’t hesitate to get in touch and we’ll always to our very best to help.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

Over the years, our team has handled everything from a single machine to complete factories for a variety of different clients and in all industries from food production to waste recycling (and everything in between). Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

Trust us to look after your machinery needs in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning. Get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call 01634 757455 or email the team at office@novatec-engineering.co.uk