Everything You Need to Know Before Engaging an Industrial Machinery Contractor

Everything You Need to Know Before Engaging an Industrial Machinery Contractor

Your machinery plays a vital role in the success of your business, so it’s vital that it’s properly installed, maintained and eventually, replaced with the latest technology.

Whilst you may have an internal maintenance team, sometimes you’ll need to enlist the help of external machinery contractors to deal with some of the more specialised aspects of your machinery care. This article should help you to understand what separates a good industrial machinery contractor from the rest.

Consider the options

When looking for an industrial machinery contractor, you need to ensure the companies you shortlist have skilled and experienced personnel, trained to install, disassemble, repair, reassemble, move, and provide ongoing maintenance to ensure proper machine efficiency and increased productivity in your operation.

Here are some of our tips for finding the right machinery contractor:

- Do Some Research – There are a number of good machinery contractors available and unfortunately, a lot of not so good. Speak to a few and get a feel for those you want to investigate further. Then use the following tips to help make your final selection.

- Check References – An experienced professional machinery contractor will have any number of previous case studies to provide you with confidence that they’ve handled similar challenges in the past. Don’t be afraid to ask for evidence of similar jobs completed and references from previous customers – If they’re anything like Novatec, they’ll be proud to show you what they’ve been up to!

- Availability of resources – The variety of machinery projects likely to be encountered by a professional rigging contractor should mean that they have an equal variety of specialist plant, tools and equipment at their disposal to provide the best solution to a given problem. When discussing your project needs with a proposed contractor, ask what equipment they propose to use and what alternatives may be available. Before bringing any plant or equipment onto your site, a professional machinery contractor should be able to provide you with evidence of a valid safety inspection record or certificate for the equipment, as well as certificates of competence for its operators and daily inspection records while in use.

- Safety is an important aspect to consider when hiring a machinery contractor. Handling heavy machinery and its associated components comes with high risks to personnel and property. A good machinery contractor will carefully and systematically plan the work, document the procedures, risks and countermeasures and will control the working environment for the safety of everyone likely to be affected by the work. Ask your proposed contractor for evidence of past accidence & incidents, method statements & risk assessments and for details of any third-party safety accreditation (if they don’t have these details, they probably don’t have very good safety controls and procedures in place).

- Look for a cost-effective option – Whilst we’d never suggest the cheapest price should be a priority, it’s important to ensure that the final choice offers the most effective solution for your budget and addresses all the potential issues to provide a safe, timely and cost-conscious solution. A professional machinery contractor will always take the time to explain how a cost has been developed. We at Novatec Engineering have certainly been called on a number of times in the past to rectify problems caused by a cheaper machinery contractor – ultimately costing the project more in the long run.

- Check insurances – many of the smaller contractors out there will try to get by on Public Liability insurance alone when handling your machinery. Unfortunately, this will probably leave you out of pocket in the event they damage the machine being handled or worked on. It’s important to check they have specific contractor’s insurance, covering the activities being carried out on your equipment, usually including: dismantling, transit, erection, positioning, loading, unloading, hot works, etc. Also check the value insured is enough to actually cover the replacement cost of your machinery, should the need arise.

What can your machinery contractor do for you?

Once you’ve found a machinery partner you can rely on, they should be capable of helping you with:

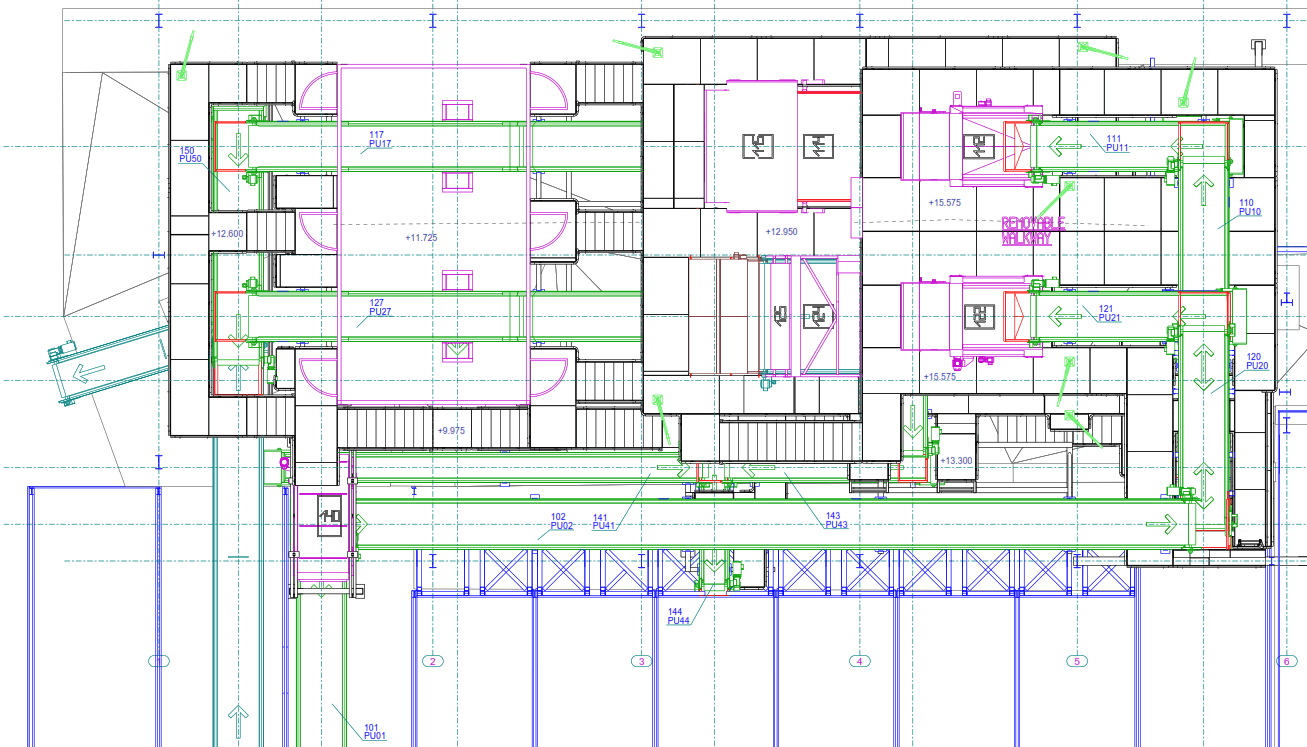

- Reading and understanding machinery schematics, circuit diagrams and process flow diagrams. The designs and operating processes of many modern industrial machines are increasingly more complex, which means your machinery contractor must possess the right knowledge and skills in troubleshooting and repair.

- Safely carrying out rigging operations to pick and place various machines and their component parts.

- Replacing old machinery with the latest model.

- Testing and troubleshooting machines after assembly and installation of the machine, working with the OEM as appropriate.

- Preparing machinery status reports and identifying ongoing maintenance requirements.

- Using a variety of tools and equipment to ensure the correct installation and maintenance of the machinery, including laser-alignment tools, vibration analysis, non-destructive testing, welding operations, machine levels, etc.

- Following standard safety protocols and regulations to ensure the prevention of workplace accidents and other potential hazards.

Don’t just settle

The importance of hiring an experienced machinery contractor cannot be underestimated, especially when relocating large, heavy machinery.

Disassembling a piece of industrial equipment can be as complex as assembling it in the first place, sometimes more so, and the right contractor will have the knowledge and expertise in dismantling, categorising, and packaging each part, safely, for onward travel.

A professional will also have specific training in the use of a variety of plant, including high-capacity forklift trucks, hoists, cranes, winches, and other equipment to safely move and store dismantled machine parts.

Don’t risk your machinery or the safety of your personnel - Trust Novatec’s experience and expertise to get the job done properly

If your company is planning to expand, move to a new facility, or simply needs a reliable contractor to carry out maintenance on your heavy machinery, please get in touch with Novatec Engineering to discuss your requirements. We’re always available to advise and help to develop your plans to ensure they translate to a safe, efficient and well executed project.

Over the years, our team has handled everything from a single machine to complete factories for a variety of clients and in all industries from food production to waste recycling (and everything in between). Regardless of the size of the project, our team follows the same strict procedures to ensure your machinery is handled safely and efficiently and is back in operation to suit your requirements.

Trust us to look after your machinery needs in every aspect, from planning and management to decommissioning, movement, re-installation and commissioning.

Get in touch with our friendly team and we’ll be only too happy to advise on the next steps for your project.

Call 01634 757455 or email the team at office@novatec-engineering.co.uk